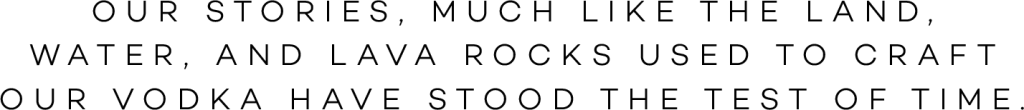

Life isn't just about drinking;

It’s about savoring moments that become lasting memories. We’re the spirit of connection!

A Smooth Journey Start

In the heart of Minnesota’s fertile lands, we source a unique strain of organic corn that defines Adam Vodka’s distinctive taste. This exceptional corn, grown in nutrient-rich soil, is the key to the subtle flavors of cocoa, vanilla, and a hint of sweetness in our vodka.

Perfected by Nature in Portland, OR

Sourced from Minnesota’s organic corn fields, Adam Vodka is then brought to life in Portland, Oregon, through a meticulous process: distilled five times for unmatched purity, and filtered through lava rock charcoal to achieve its signature smoothness and distinct character.

TO CREATE A WORLD OF ELEVATED CONNECTIONS

Adam Vodka is crafted to elevate connections and transform social experiences. From the rich soil of Minnesota to the artful distillation in Portland, we create a vodka that turns gatherings into memorable moments. It’s not just about savoring a premium spirit—it’s about fostering the meaningful interactions that life is truly about. Join us in creating a world of elevated connections.

5x Awards

VODKA awards 2024

IS JUST THE BEGINNING

You may not have heard of us, but we’ve been here all along.

2019

The year of

2018

2019

2020

2021

2023

We ship nation-wide.

From California, with ❤️

You must be of legal drinking age to buy Adam Vodka. 21+